ENSURING MANUFACTURING EXCELLENCE

DELIVER EXCEPTIONAL RESULTS

SilTerra’s Multi Project Wafer (MPW) program is a cost-effective, multi-project design and IP verification service for Customers and IP providers.

This is a program which runs regularly. The program enables multiple customers to participate while sharing mask costs.

The tentative tape-out schedule is shown as below:

Note:

– The above schedule is subject to change

– The final GDS database for C18 BCD and eFlash design to be submitted ONE WEEK before the shuttle closing date

| FA Technique | Applications |

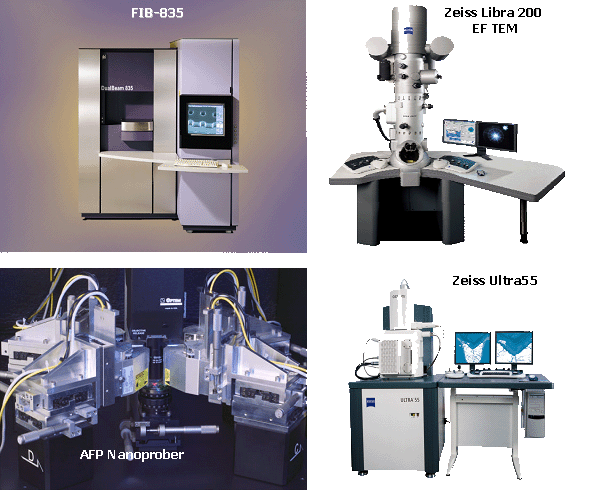

| Focused Ion Beam (FIB) | Cross-section, circuit modification, high resolution inspection, Passive Voltage Contrast (PVC); |

| Field-Emission Scanning Electron Microscopy (FE-SEM) | High resolution inspection, Passive Voltage Contrast (PVC); |

| Energy Dispersive X-ray Spectometry (EDX) | Qualitative and quantitative elemental analysis; |

| Sela Micropoint Cleaving System | Micro precision cleaving; |

| Scanning Laser Optical microscope (InGaAs, VBA, Thermal) | Fault isolation to determine emission spot; |

| Liquid Crystal | Fault isolation to determine emission spot; |

| AFP Nanoprober + Parametric Analyzer | Electrical prober on sub-micron features; IV curve trace, static electrical anaylsis; |

| IC Decapsulator | Package IC decapsulation; |

| FA Technique | Applications |

| Electrical Parametric Analysis | Validate functionality of DC performance of IC; |

| Bitmap Engineering + Auto Prober | Test for bitmapping to locate failed bit location; |

| Optical / UV Microscopy | High magnification inspection up to 1,500x; |

SilTerra FAS Capabilities

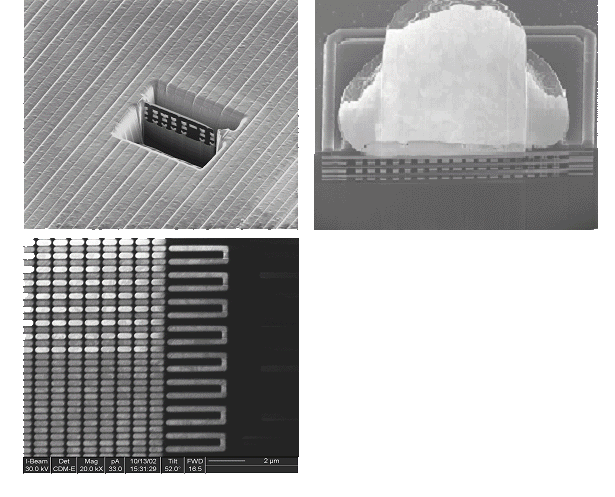

Focus Ion Beam (FIB)

Advance FIB for Voltage Contrast, Micro-X-section image and composition for defect, particle, structure etc.

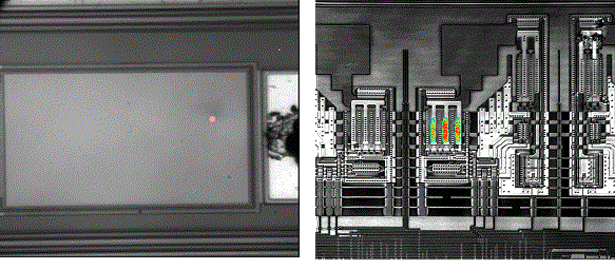

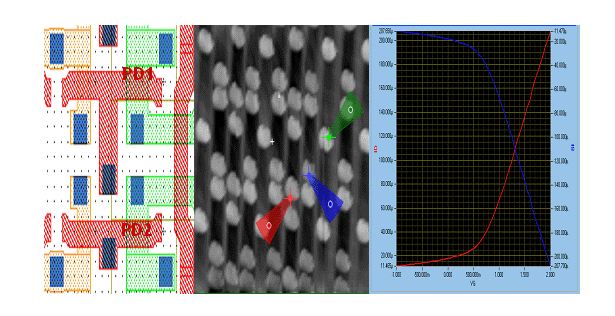

Photon Emission Microscopy & Scanning Laser Optical Microscope

Hot Spot found from EMMI analysis

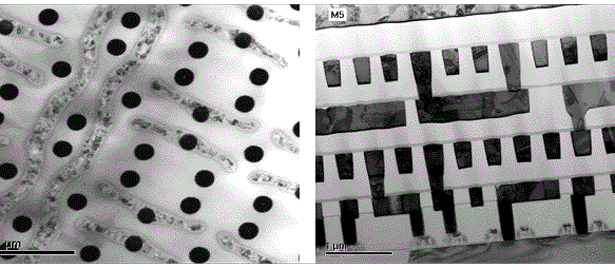

TEM

TEM Scanning – Planar View and X-section for Ultra High Magnification

FE – SEM

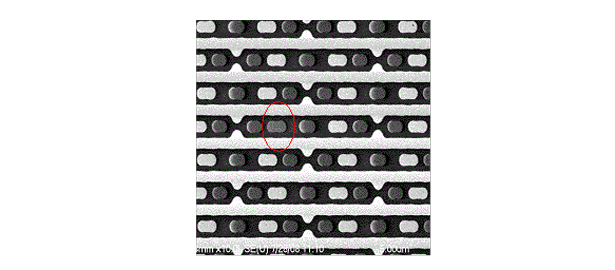

SEM Scanning – Voltage Contrast and X-section for Ultra HIgh Magnification

AFP Nanoprober and Parametric Analyzer

Nano probing on SRAM failed Bit and IV Parametric Measurement

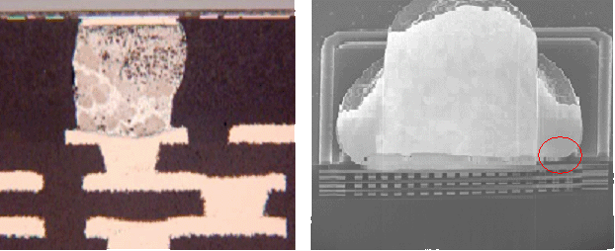

Cross sectioning to check for Bond pad structure and Solder bump integrity

SilTerra partners with third party photo mask vendors to offer seamless mask-making services. Our photo mask partners are prudently selected through rigorous product and process qualifications, data checks and inline monitoring to ensure the highest quality in our mask services.

SilTerra’s mask service qualification covers accurate GDS file processing, precise mask data preparation, OPC conversion validation and zero-defect mask manufacturing prior to the delivery of these photo masks to SilTerra for wafer production.

With stringent photo mask qualification procedures in place, SilTerra is able to ensure that the photo masks shipped to the fab are accurately matched and optimized for SilTerra’s process capabilities, which will in turn ensure repetitive high wafer yield for our customers’ products.

Below are SilTerra’s qualified Photo Mask vendors:

Metallic Thin-Film Materials :

Al, Cu + Cap layer, TiN, Ti, W, Cobalt, TiAlN, AlN, Moli, Ta and TaN.

Non-Metallic Thin-Film Materials :

Oxide, SiO2, SiN, TEOS, FSG, USG, BPSG.

My Vendor Portal provides SilTerra’s approved vendors a “one-stop” secure online access to submit vendor quality-related records such as CA/COC certification, Quality Reports and Others. It also enables vendors to access SilTerra’s specs, review revision notifications and provide updates for 8D report (SCAR) corrective actions.

Note: SilTerra will only issue a login access to vendors that are required to perform the above-mentioned tasks. A SilTerra personnel will be in touch with the respective vendor to communicate the login details.

This is an online system to facilitate Online Pickup Order Form (ePOF).

Once the registration form is submitted, it is subjected to review and approval prior to be qualified by SilTerra Shipping Department.